We’re at war with COVID-19. What lessons can we learn from World War II?

Blinking Owl Distillery produces just 1,000 bottles a week of its vodka, gin and other spirits handcrafted from organic grains out of its repurposed corrugated metal hut in a Santa Ana industrial district.

So, after government orders forced the microdistillery to close March 17 and owners Robin and Brian Christenson furloughed four bartenders from its tasting room, they were thrilled to get a call from Orange County. Would the distillery be interested in producing some critically needed hand sanitizer?

“It’s an entirely different business and regulations, but a couple of weeks ago when we saw that the Purell shortage was going on, we thought about it and were like, ‘Wait a minute, we make high-proof alcohol. We could do this,’” said Robin, whose husband, Brian, has taken to calling their product “craft small-batch hand sanitizer.”

The couple expect they can sell some 4,000 gallons a week for first responders and buyers such as hospitals, which have ordered it by the drum. They plan on lowering costs by making it from corn, and if sales keep the lights on and their single distiller employed, that’s good enough for them. It’s also good enough for the federal government, which has been trying by hook or by crook to increase supplies.

The federal Alcohol and Tobacco Tax and Trade Bureau has issued emergency regulations allowing distillers to begin immediate production, while the U.S. Food and Drug Administration has issued its own relaxed guidelines for companies not licensed or registered as drug manufacturers to produce sanitizer.

Blinking Owl isn’t the only distillery that has moved into sanitizer. Spirits giant Pernod Ricard was lauded by President Trump for cranking out big volumes of the virus killer, while companies in different industries are switching to producing other critically needed supplies as the number of confirmed cases of COVID-19, the disease caused by the coronavirus, exceeded 100,000 and deaths topped 1,700 in the United States on Friday evening.

Los Angeles apparel companies are making masks, as is Hanesbrands Inc., a large North Carolina manufacturer of underwear. It will start making FDA-approved nonsurgical masks as part of a consortium that could produce as many as 6 million per week, while companies such as Apple and Facebook are donating to healthcare workers millions of reserve masks they have stockpiled.

General Motors is working with Ventec Life Systems to radically increase its production of ventilators, with the two companies announcing Friday — amid a public tussle with Trump, who wants them delivered faster and cheaper — that the automaker will build the devices at GM’s Kokomo, Ind., manufacturing facility and ship them as soon as next month. GM said it will also be making FDA-cleared Level 1 surgical masks at its Warren, Mich., plant.

Ford and Toyota also have said they‘re working with medical device makers to produce ventilators and other equipment, while Tesla Chief Executive Elon Musk has tweeted that he’s working with Medtronic to build ventilators and will reopen a New York factory to assist in production.

Call it war mobilization.

The unprecedented $2-trillion stimulus package Trump signed Friday is roughly twice the size of what was adopted in response to the 2007-08 financial crisis amid a record surge this week of 3.3 million unemployment claims.

Trump has cast himself as a wartime president, saying, “In a true sense we’re at war and we’re fighting an invisible enemy.”

Senate Majority Leader Mitch McConnell (R-Ky.) frames it this way: “A fight has arrived on our shores.”

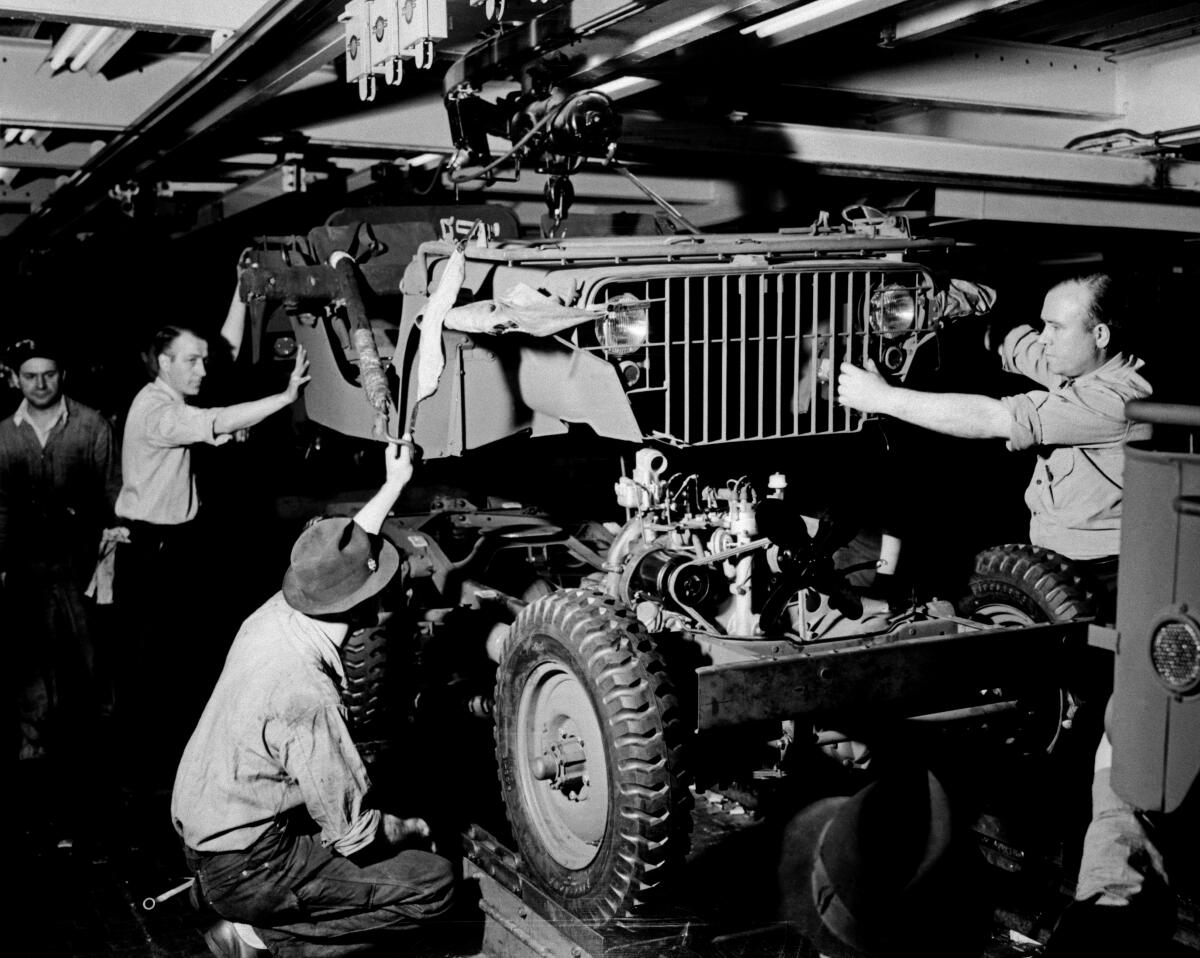

The response so far doesn’t approach the Chinese government’s construction of two hospitals in a little over a week to treat COVID-19 patients, let alone the U.S. response during World War II, when Detroit automakers were ordered to stop passenger car production and put all their resources into tanks, military trucks, jeeps and other war materiel.

But with California Gov. Gavin Newsom projecting the state may be short 17,000 hospital beds and New York officials fearing the city and state may be overwhelmed with cases, there have been calls even from Republicans for a stronger federal response through the utilization of a Korean War-era act to order companies to ramp up production of critical supplies — something Trump finally did Friday with a single company, GM.

“If I had the power, I would do it in New York state because the situation is that critical” New York Gov. Andrew Cuomo said during a March 22 briefing.

The Defense Production Act, modeled after the broad war powers President Franklin D. Roosevelt was handed during World War II, gives the government authority to purchase and distribute critically needed supplies before other buyers, and even order companies to produce goods on an emergency basis.

Trump signed an executive order March 18 giving Health and Human Services Secretary Alex Azar authority to put the act to use against the virus outbreak. But it was not until Friday that he told Azar to order GM to “accept, perform, and prioritize Federal contracts for ventilators,” contending that “GM was wasting time” and the action would save lives.

Friday’s order came despite pushback from the U.S. Chamber of Commerce, and the president’s own misgivings. Last Sunday, Trump said, “We’re not a country based on nationalizing our business,” though the government doesn’t have the authority to take ownership of a company under the act, even if it can direct operations.

The 1950 law was signed by President Truman after the outbreak of hostilities on the Korean peninsula and was intended to rapidly build up the military. It had other provisions, including wage and price controls, that have since been rescinded, but others have remained in place or even been strengthened.

For example, the U.S. has invoked a provision of the act to rebuild its rare-earth metals industry, which is now controlled by China but is critical to the manufacture of cellphones, missiles and wind turbines. Another provision allows national security reviews of private businesses and transactions such as the popular social media platform TikTok, which is being probed for its ties to China.

Though the law stems from the Korean conflict, it is the Second World War that perhaps more closely mirrors the global battle that has broken out against the coronavirus, which has spread to every continent except Antarctica and chased billions of people out of their workplaces and into their homes.

In response to the Nazi aggression in Europe and the Japanese bombing of Pearl Harbor, the U.S. created an alphabet soup of federal agencies that rivaled the New Deal. Among them were the War Production Board, the Office of War Mobilization, the Office of Price Administration and the War Food Administration.

Yet the government nearly fumbled the ball at first, trying to lure the private sector into building a war machine using financial tools such as tax incentives and accelerated write-offs of capital investments, said Alexander Field, an economics professor at the Leavey School of Business at Santa Clara University.

“It was not ‘snap our fingers, we are going to build 100,000 aircraft,’” said Field, who is now writing an economic history of the period and sees parallels to today’s struggle against the coronavirus. “Many manufacturers did not want to use their own funds to build specialized facilities and acquire special-purpose machine tools to manufacture goods that they knew would have a limited shelf life. We bumbled a lot in World War II, and with a really determined effort we could have screwed it up and lost the war.”

Mark Wilson, a history professor at the University of North Carolina at Charlotte, said the government ultimately realized that the fastest way to get the war materiel it needed was to simply finance the construction of new factories and then have private corporations with expertise run them — so-called GOCO (government-owned, contractor-operated) plants — or to simply guarantee the government would purchase the products the private sector produced.

“If you wait for the private companies and the bankers to calculate whether this is going to make sense for them economically, you can just create artificial delays,” said Wilson, who wrote a 2016 book, “Destructive Creation,” arguing that plants newly built by the government to produce ships, aircraft, tanks and other key materiel played a bigger role in the war effort than conversions of existing plants did.

“They did it remarkably quickly in a matter of months, but it was not something you could turn on in a matter of days,” he said, adding that the pace could likely be increased by modern technology such as computer-aided design and modular construction (which the Chinese used to build their two hospitals).

Today we need gear and supplies such as hospitals and beds, ventilators and masks, test kits and cleaning agents. And even if the production is vast, it would probably amount to a fraction of the $3 trillion or more in today’s dollars spent during World War II by industry and government on manufacturing and equipment, according to one estimate.

Still, World War II can provide a road map, Wilson said, with the government guaranteeing the purchase of medical equipment, and encouraging and overseeing the licensing and sharing of proprietary designs, which was how General Motors and Ford were able to build aircraft engines designed by Pratt & Whitney in the 1940s.

Indeed, today, the big automakers are working with various medical device makers to ramp up ventilator production, while Hanesbrands said it plans to share its mask design with other apparel makers.

Wilson added that “great calamities” such as the Depression and World War II turned out to stretch for years, and authorities should not make the mistake of worrying about overproduction or waste and “not needing it in the end.” Field noted that whatever equipment healthcare providers do not need after the outbreak subsides could be stockpiled by the government for a strategic reserve.

The giant war mobilization effort also had the effect of driving down the unemployment rate, which averaged 9.9% in 1941 but fell to less than 2% as the conflict ground on — a consideration today as millions are being laid off due to the virus outbreak.

Americans also can take heart in how fast the government and manufacturers were able to respond when the U.S. faced a manufacturing crisis in 1942 after Japan invaded Singapore. That cut off 90% of the country’s supply of natural rubber, forcing the U.S. to establish a synthetic rubber industry at breakneck speed.

“We had no domestic sources of natural rubber. That was a real potential catastrophe. It was close,” Field said, noting the government’s Defense Plant Corp. ultimately spent about $800 million to build 51 factories that were not privatized until 1955.

Jerry McGinn, a former Defense Department official who oversaw implementation of the Defense Production Act from 2015 to 2018, said that building facilities under the act requires the government and companies to share the capital investment and companies to document their expenses and pricing so profits are “fair and reasonable.”

After the contract is over, the government turns over ownership to the company for a nominal fee but retains perpetual rights to production when needed.

The current bureaucratic process, involving requests for proposals and other steps, to get rare-earth metals plants built will probably take about 18 months before dirt is even turned. However, McGinn said, the timeline could be sped up to deal with the coronavirus.

“This being the Manhattan Project, you can accelerate dramatically by perhaps half, but it is just not going to happen in a week,” said McGinn, who is now executive director of the Center for Government Contracting at George Mason University’s business school.

Another faster way for the government to contract for what it needs, he said, is for officials to simply “throw money” at an industry, such as by designing and producing goods through pilot projects. “There are lots of different ways that the government can engage with industry to meet a need; some of these are really rapid,” he said.

In his public spat with GM CEO Mary Barra, Trump tweeted Friday that the company “said they were going to give us 40,000 much needed Ventilators, ‘very quickly’. Now they are saying it will only be 6000, in late April, and they want top dollar. Always a mess with Mary B. Invoke ‘P,’” later clarifying P stood for the Defense Production Act.

In their own joint statement Friday, GM and Ventec said that they were working “around the clock” and that retooling of the GM Kokomo facility was already underway to produce more than 10,000 per month, multiple times more than Ventec can make on its own. The statement said the companies had developed a global supply base for the more than 700 individual parts that are required.

Erik Gordon, a professor at the University of Michigan’s Ross School of Business, said the auto industry’s initiative highlights how the automakers and their suppliers can “manufacture in large quantities once they get ramped up, once they get the right tools in place to make the actual parts that are needed.”

But he said people often forget in our high-tech society that software can’t fix every problem, something to consider even as GM is working with a ventilator maker using proven, existing designs.

“You have to extrude metal, you have to bend metal, you have to weld metal because there is no such thing as a software ventilator,” he said, adding that it might take at least 30 days to retool factories to get them ready to make the parts.